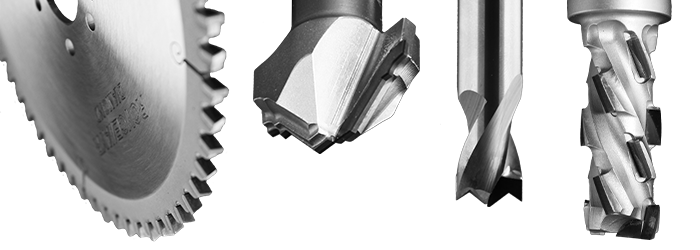

Polycrystalline Diamond (PCD)

What is it?

Polycrystalline Diamond (PCD) consists of varying sized synthetic diamond particles sintered together under extreme heat and pressure. The result is a incredibly hard, wear resistant material with exceptional thermal capabilities. What this means for you is exceptional tool life when used in the proper applications.

Where does it work?

PCD will not work in all applications. One of the weaknesses of PCD is that it is more brittle than other materials. Although advancements have been made in PCD production methods and much more impact resistant grades are available, careful considerations must be taken into account before using PCD. PCD can provide excellent cost savings when machining the following materials.

- Aluminium with higher silicon contents

- Most non-ferrous materials

- Modern fiber reinforced plastic composites

- Modern engineered construction materials

- Gypsum, limestone, and other natural construction materials

- Medium and high density fiberboard, MDF, HDF

- Secondary wood machining of clean, graded hardwoods

PCD is not recommended for the following materials and applications.

- Applications were excessive vibration is present

- Cutting of materials where hard foreign material may be present

- Machining of nested particle board

- Most ferrous materials

- Applications with poor chip removal, and re-cutting of chips is a problem

- Quartz, granite, and other hard natural stones